Quickmill Rubino Plus portafilter machine

incl. imposto sobre o valor acrescentado

Finanzieren ab 71,05 € / Monat* mit

🚚 Shipping within EU: 34 €

EU shipping costs, see shipping policy.

🚚 Shipping within EU: 34 €

EU shipping costs, see shipping policy.

Passt wunderbar dazu

Quickmill Rubino Plus portafilter machine

Quickmill Rubino PID - dual-circuit portafilter machine with precision & design

The Quickmill Rubino Plus PID combines elegant design with powerful technology. With the proven E61 brewing group, an insulated 1.8 liter stainless steel boiler and the precise PID temperature control, it offers espresso perfection at barista level. Thanks to the dual-circuit system, espresso and milk foam can be prepared simultaneously - ideal for cappuccino and latte macchiato lovers.

Highlights of the Quick Mill Rubino Plus PID

- E61 brewing group for optimum temperature stability

- PID control for precise temperature control

- Double pressure gauge for boiler and pump pressure display

- Quiet vibration pump with pulsor for gentle pressure build-up

- 2.8-liter copper boiler - insulated for greater efficiency

- 3-liter water tank, removable from the side

- Shot timer for precise extraction control

- Eco mode & standby to save energy

- No-burn steam lance with ball joint for easy handling

- Ergonomic rotary valves for precise control

- Stainless steelcup warmer on the top

Technical details

- Machine type: Dual-circuit

- Pump type: Vibration pump with pulsor

- Boiler size: 2.8 liters (stainless steel, insulated)

- PID control: Yes

- Water tank: 3 liters, removable from the side

- Pressure indicator: Double pressure gauge for boiler & pump pressure

- Heating time: approx. 10-15 minutes

- Power: 1500 W

- Dimensions (W x H x D): 26.5 x 36.5 x 45 cm

- Weight: 20 kg

What distinguishes the Rubino Plus PID from the standard Rubino?

- PID temperature control for more control over the brewing temperature

- Shot timer for precise monitoring of the extraction time

- Ergonomic rotary valves for steam and hot water

- No-burn steam lance for more convenience and safety

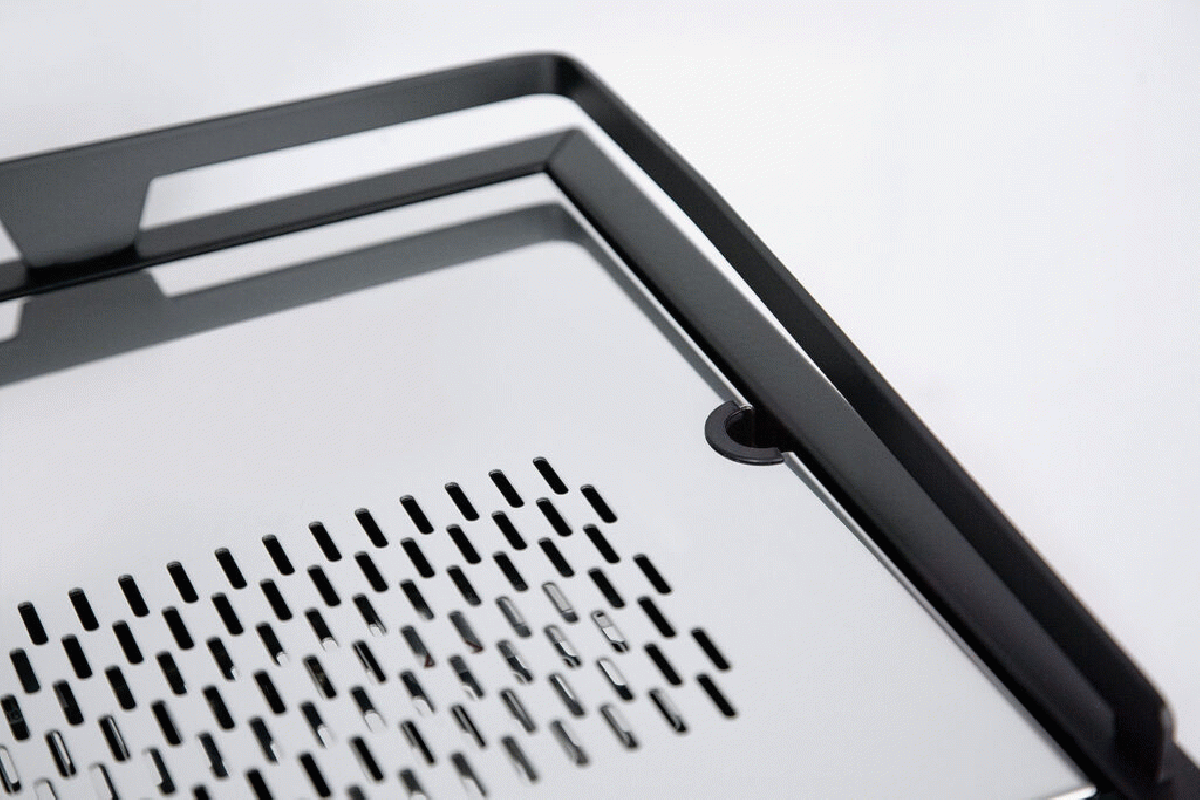

- New design with high-quality stainless steel railing

- Extended drip tray for easier cleaning

For whom is the Quickmill Rubino Plus PID the right choice?

This machine is perfect for coffee lovers who value high-quality workmanship, precise temperature control and a classic E61 design. The dual-circuit system makes it ideal for espresso and milk foam specialties and is particularly temperature-stable thanks to the powerful PID control.

Experience espresso perfection with the Quickmill Rubino Plus PID - the perfect combination of design, performance and functionality.

Detalhes do fabricante

Natural bean barista cloth 40x40

Puly Grind mill cleaner 10x15g

Eureka Tamper Station (double)

Wiedemann WDT Distribution Tool

Upgrade for your portafilter machine

Matching accessories

If you have any questions, please feel free to contact us at any time. We will get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping info

We ship all products the same day if ordered before 1pm.

-

Apoio

We will also be there to support you and advise you after your purchase. If you have any questions about the product you purchased from us, please contact us.

-

Contact

Correio eletrónico: hello@naturbohne.de

Telefone: 07454 / 870 48 64

Frequently Asked Questions

I bought a new coffee grinder from Naturbohne and there are coffee residues in it.

Please note: Some manufacturers test their coffee grinders before shipping, which means that small coffee residues or bean residues can occasionally be found in the grinder. This procedure is used to test functionality and is considered a quality feature. Of course, we only sell new products - unless expressly stated otherwise.

Static charge – coffee grounds spray out from the side

With some coffee grinders, the ground coffee can become statically charged and spray out of the portafilter at the side. This means that not all of the ground coffee gets into the portafilter, which can lead to uneven extraction. Our recommendation: Use a dosing funnel to ensure that all of the ground coffee is precisely fed into the portafilter - for optimal espresso enjoyment.

What is dead space in coffee grinders?

Conventional coffee grinders often leave a so-called dead space in which coffee residues accumulate. These residues can not only affect the freshness, but also lead to old and fresh coffee grounds being mixed, which negatively affects the taste. In contrast, single dose grinders have a well-thought-out design that eliminates the dead space. Each portion is ground individually and precisely so that no residues are left behind - for a consistently pure and full-bodied coffee experience.

Which portafilter fits my espresso machine?

When choosing the right portafilter for your portafilter machine, it is important to know that each manufacturer develops its own brewing group - the most well-known is the Faema E61. However, this does not mean that any portafilter will fit without any problems. An incompatible portafilter can leak, which will have a direct negative impact on the quality of your espresso. We therefore recommend using either the portafilter originally supplied or one that is explicitly stated to be compatible with your machine. This will ensure that the pressure is optimally built up and the espresso is perfectly extracted.

Can I visit you or pick up the goods personally?

Yes, of course, you are welcome to come by and look at our products by appointment. We would be happy to advise you personally. The best thing to do is to send us an email with a few suggested appointment times.

We are located 5 minutes from the motorway between Stuttgart and Lake Constance on the edge of the Black Forest.

Important note, first use coffee grinders

Another little tip for the perfect start with your new mill:

You will get the best grinding result after you have ground about 1-2 kg of beans. It is best to use a few cheap beans so that the grinder can work optimally. And if you are wondering what you can do with the bean flour - it is perfect plant fertilizer! 🌿

It contains nitrogen, potassium, sulfur and phosphorus and is a real nutrient bomb for your plants.

Podem efetuar uma calibração de desvio na minha máquina de porta-filtros?

Existem alguns argumentos contra a calibração offset para as máquinas de porta-filtros Lelit, especialmente para modelos como a Lelit Bianca. Estes argumentos prendem-se principalmente com a complexidade e as limitações do offset como única solução para os problemas de temperatura:

- Flutuações de temperatura e instabilidade. O offset tem em conta uma diferença constante entre a temperatura da caldeira e a temperatura de fabrico da cerveja. Na prática, porém, podem ocorrer flutuações de temperatura, por exemplo, devido a tempos de repouso mais longos ou ao fabrico contínuo de cerveja. Como resultado, a temperatura real de fermentação nem sempre pode ser prevista com precisão.

- Dependência das condições ambientais. Factores como a temperatura ambiente, a humidade e o estado da máquina (por exemplo, o tempo de aquecimento) têm uma influência significativa na temperatura de infusão. Um desvio fixo não pode compensar dinamicamente estas variáveis, o que pode levar a resultados inexactos.

- Perda de calor durante os tempos de paragem. Após pausas mais longas, o grupo de cerveja arrefece e a máquina precisa de tempo para voltar à temperatura desejada. Um offset corretamente ajustado não pode compensar este facto, pelo que são necessárias medidas adicionais como um "cooling flush".

- Calibrações de fábrica incorrectas. Em alguns modelos Lelit, verificou-se que a compensação de fábrica é frequentemente definida de forma incorrecta (por exemplo, 4-8 graus demasiado baixos na Lelit Bianca). Isto requer uma recalibração manual por pessoal especializado, o que pode ser complicado para os utilizadores finais.

- Mal-entendidos na aplicação. Muitos utilizadores ficam confusos com informações contraditórias sobre a definição do desvio, o que pode levar a ajustes incorrectos. Por exemplo, muitas vezes espera-se que o offset por si só resolva todos os problemas de temperatura, embora seja apenas uma parte de um sistema mais complexo.

Conclusão

A calibração do desvio é uma ferramenta útil, mas não deve ser considerada isoladamente. É necessária uma combinação de controlo preciso do PID, manutenção regular e técnicas personalizadas (por exemplo, injecções de enxaguamento) para obter os melhores resultados de fabrico de cerveja.

Do you have any more questions?

Contact

If you have any questions about our products, please write to us here or use the chat function.