Quickmill Rubino Plus portafilter machine

TVA incluse

Finanzieren ab 69,32 € / Monat* mit

🚚 Shipping within EU: 34 €

EU shipping costs, see shipping policy.

🚚 Shipping within EU: 34 €

EU shipping costs, see shipping policy.

Passt wunderbar dazu

Quickmill Rubino Plus portafilter machine

Quickmill Rubino PID - dual-circuit portafilter machine with precision & design

The Quickmill Rubino Plus PID combines elegant design with powerful technology. With the proven E61 brewing group, an insulated 1.8 liter stainless steel boiler and the precise PID temperature control, it offers espresso perfection at barista level. Thanks to the dual-circuit system, espresso and milk foam can be prepared simultaneously - ideal for cappuccino and latte macchiato lovers.

Highlights of the Quick Mill Rubino Plus PID

- E61 brewing group for optimum temperature stability

- PID control for precise temperature control

- Double pressure gauge for boiler and pump pressure display

- Quiet vibration pump with pulsor for gentle pressure build-up

- 2.8-liter copper boiler - insulated for greater efficiency

- 3-liter water tank, removable from the side

- Shot timer for precise extraction control

- Eco mode & standby to save energy

- No-burn steam lance with ball joint for easy handling

- Ergonomic rotary valves for precise control

- Stainless steelcup warmer on the top

Technical details

- Machine type: Dual-circuit

- Pump type: Vibration pump with pulsor

- Boiler size: 2.8 liters (stainless steel, insulated)

- PID control: Yes

- Water tank: 3 liters, removable from the side

- Pressure indicator: Double pressure gauge for boiler & pump pressure

- Heating time: approx. 10-15 minutes

- Power: 1500 W

- Dimensions (W x H x D): 26.5 x 36.5 x 45 cm

- Weight: 20 kg

What distinguishes the Rubino Plus PID from the standard Rubino?

- PID temperature control for more control over the brewing temperature

- Shot timer for precise monitoring of the extraction time

- Ergonomic rotary valves for steam and hot water

- No-burn steam lance for more convenience and safety

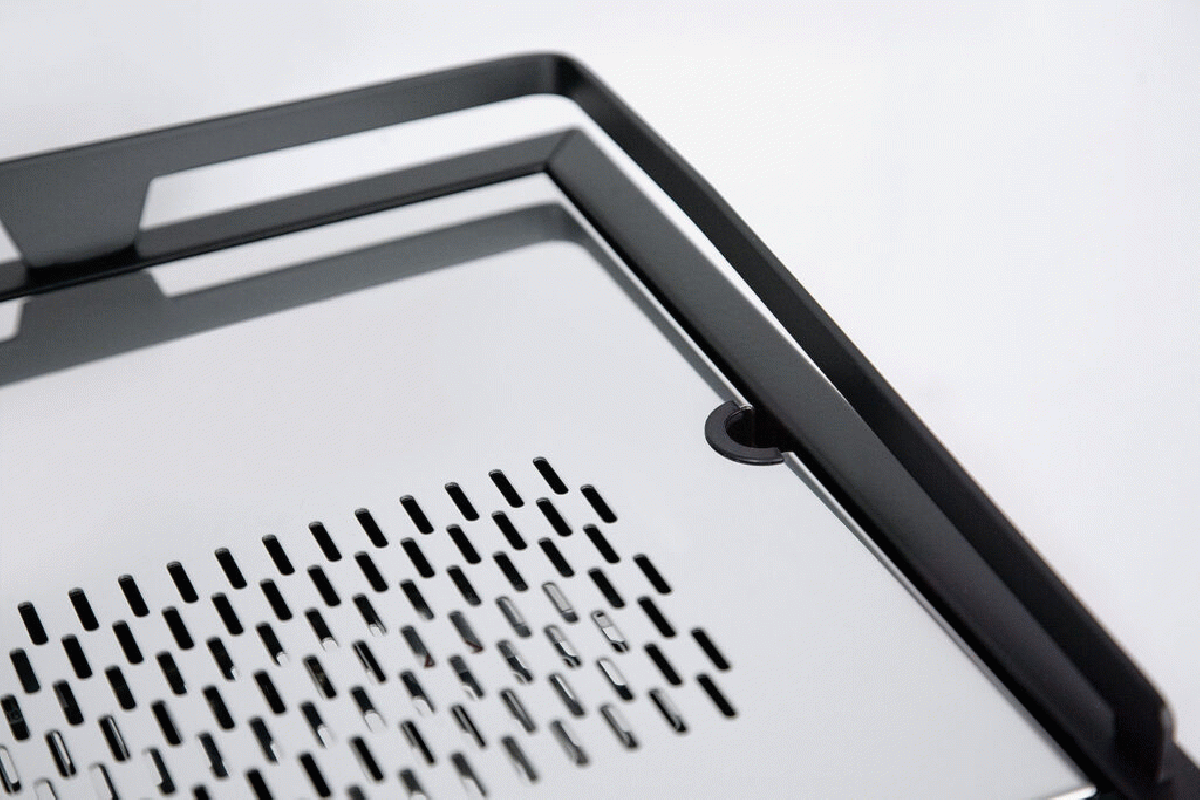

- New design with high-quality stainless steel railing

- Extended drip tray for easier cleaning

For whom is the Quickmill Rubino Plus PID the right choice?

This machine is perfect for coffee lovers who value high-quality workmanship, precise temperature control and a classic E61 design. The dual-circuit system makes it ideal for espresso and milk foam specialties and is particularly temperature-stable thanks to the powerful PID control.

Experience espresso perfection with the Quickmill Rubino Plus PID - the perfect combination of design, performance and functionality.

Informations sur le fabricant

Natural bean barista cloth 40x40

Puly Grind mill cleaner 10x15g

Eureka Tamper Station (double)

Wiedemann WDT Distribution Tool

Upgrade for your portafilter machine

Matching accessories

If you have any questions, please feel free to contact us at any time. We will get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping info

We ship all products the same day if ordered before 1pm.

-

Soutien

We will also be there to support you and advise you after your purchase. If you have any questions about the product you purchased from us, please contact us.

-

Contact

Email : hello@naturbohne.de

Téléphone : 07454 / 870 48 64

Frequently Asked Questions

I bought a new coffee grinder from Naturbohne and there are coffee residues in it.

Please note: Some manufacturers test their coffee grinders before shipping, which means that small coffee residues or bean residues can occasionally be found in the grinder. This procedure is used to test functionality and is considered a quality feature. Of course, we only sell new products - unless expressly stated otherwise.

Static charge – coffee grounds spray out from the side

With some coffee grinders, the ground coffee can become statically charged and spray out of the portafilter at the side. This means that not all of the ground coffee gets into the portafilter, which can lead to uneven extraction. Our recommendation: Use a dosing funnel to ensure that all of the ground coffee is precisely fed into the portafilter - for optimal espresso enjoyment.

What is dead space in coffee grinders?

Conventional coffee grinders often leave a so-called dead space in which coffee residues accumulate. These residues can not only affect the freshness, but also lead to old and fresh coffee grounds being mixed, which negatively affects the taste. In contrast, single dose grinders have a well-thought-out design that eliminates the dead space. Each portion is ground individually and precisely so that no residues are left behind - for a consistently pure and full-bodied coffee experience.

Which portafilter fits my espresso machine?

When choosing the right portafilter for your portafilter machine, it is important to know that each manufacturer develops its own brewing group - the most well-known is the Faema E61. However, this does not mean that any portafilter will fit without any problems. An incompatible portafilter can leak, which will have a direct negative impact on the quality of your espresso. We therefore recommend using either the portafilter originally supplied or one that is explicitly stated to be compatible with your machine. This will ensure that the pressure is optimally built up and the espresso is perfectly extracted.

Can I visit you or pick up the goods personally?

Yes, of course, you are welcome to come by and look at our products by appointment. We would be happy to advise you personally. The best thing to do is to send us an email with a few suggested appointment times.

We are located 5 minutes from the motorway between Stuttgart and Lake Constance on the edge of the Black Forest.

Important note, first use coffee grinders

Another little tip for the perfect start with your new mill:

You will get the best grinding result after you have ground about 1-2 kg of beans. It is best to use a few cheap beans so that the grinder can work optimally. And if you are wondering what you can do with the bean flour - it is perfect plant fertilizer! 🌿

It contains nitrogen, potassium, sulfur and phosphorus and is a real nutrient bomb for your plants.

Pouvez-vous effectuer un calibrage offset sur ma machine à porte-filtre ?

Il existe plusieurs arguments contre un calibrage d’offset sur les machines à levier Lelit, en particulier pour des modèles comme la Lelit Bianca. Ceux-ci concernent surtout la complexité et les limites de l’offset comme solution unique aux problèmes de température :

- Fluctuations et instabilité de la température. L’offset prend en compte une différence constante entre la température de la chaudière et celle de l’extraction. En pratique, des variations de température peuvent survenir, par exemple après de longs temps d’arrêt ou lors d’extractions continues. Ainsi, la température réelle d’extraction n’est pas toujours précisément prévisible.

- Dépendance aux conditions ambiantes. Des facteurs comme la température de la pièce, l’humidité de l’air et l’état de la machine (par exemple, le temps de chauffe) influencent fortement la température d’extraction. Un offset fixe ne peut pas compenser dynamiquement ces variables, ce qui peut entraîner des résultats imprécis.

- Perte de chaleur lors des périodes d’inactivité. Après une longue pause, le groupe d’extraction refroidit et la machine a besoin de temps pour revenir à la température souhaitée. Un offset correctement réglé ne peut pas compenser cela, d’où la nécessité de mesures supplémentaires comme un « cooling flush ».

- Calibrages incorrects en usine. Sur certains modèles Lelit, il a été constaté que l’offset est souvent mal réglé en usine (par exemple, 4 à 8 degrés trop bas sur la Lelit Bianca). Cela nécessite un recalibrage manuel par un professionnel, ce qui peut être compliqué pour les utilisateurs finaux.

- Malentendus dans l’utilisation. De nombreux utilisateurs sont déconcertés par des informations contradictoires sur le réglage de l’offset, ce qui peut entraîner de mauvais réglages. Par exemple, on s’attend souvent à ce que l’offset résolve à lui seul tous les problèmes de température, alors qu’il ne constitue qu’une partie d’un système plus complexe.

Conclusion

Le calibrage de l’offset est un outil utile, mais il ne doit pas être considéré isolément. Une combinaison d’un contrôle PID précis, d’un entretien régulier et de techniques adaptées (par exemple, des « spülshots ») est nécessaire pour obtenir des résultats d’extraction optimaux.

Do you have any more questions?

Contact

If you have any questions about our products, please write to us here or use the chat function.