Eureka Black Diamond grinding discs

excluding VAT, excluding shipping costs

Finanzieren ab 6,15 € / Monat* mit

🚚 Shipping within EU: 8 €

EU shipping costs, see shipping policy.

Passt wunderbar dazu

Eureka Black Diamond grinding discs

All Purpose grinding discs

Eureka burrs are specially designed to deliver outstanding results for both espresso and filter coffee. They are ideal for all types of coffee, especially light and medium roasts, as they bring out the clarity and brightness of the aromas.

Unlimited Stamina

Thanks to the innovative treatment technologies, the grinding discs offer greater durability than any other grinding disc treatment on the market.

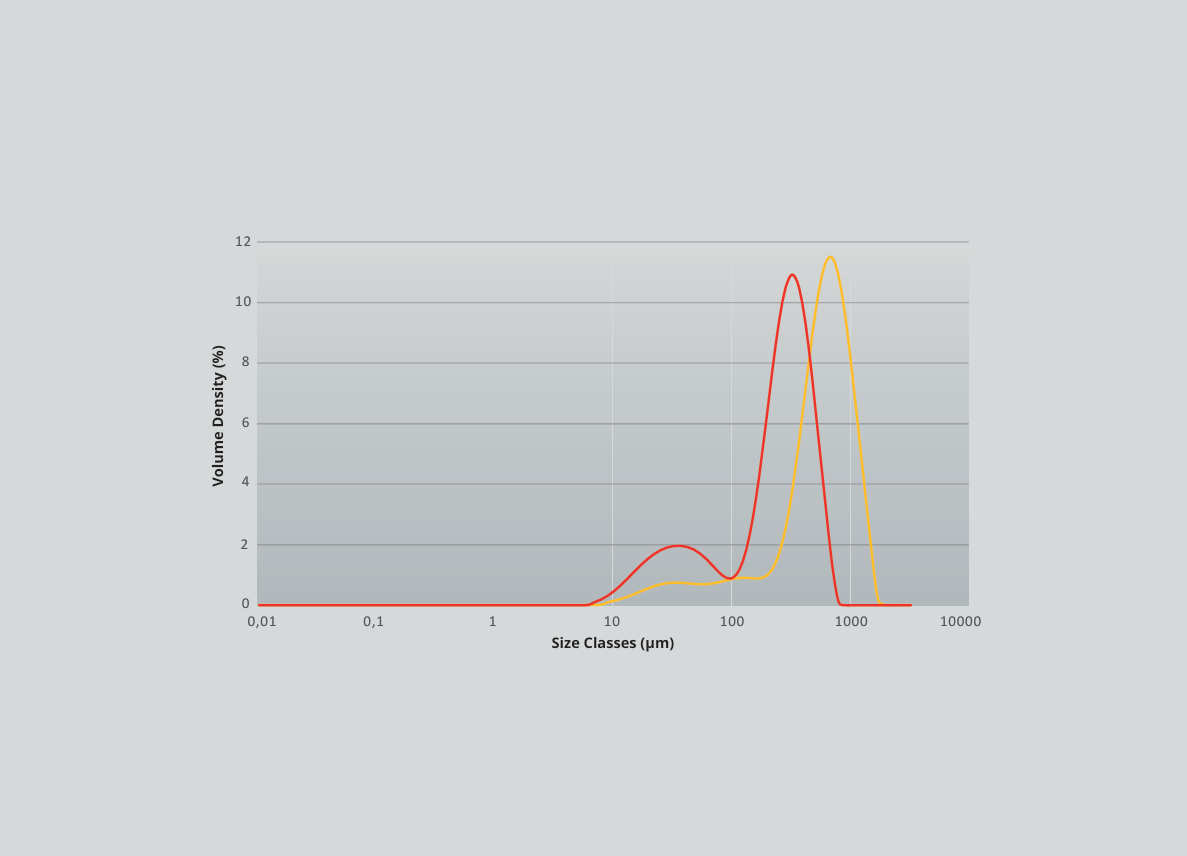

Excellent grinding disc consistency

The thermal cryo-treatment cools the grinding discs down to -193°C. This technology makes the grinding discs particularly robust and provides two decisive advantages: a significantly longer service life and a consistently consistent grinding result without adjustment of the grinding level over time.

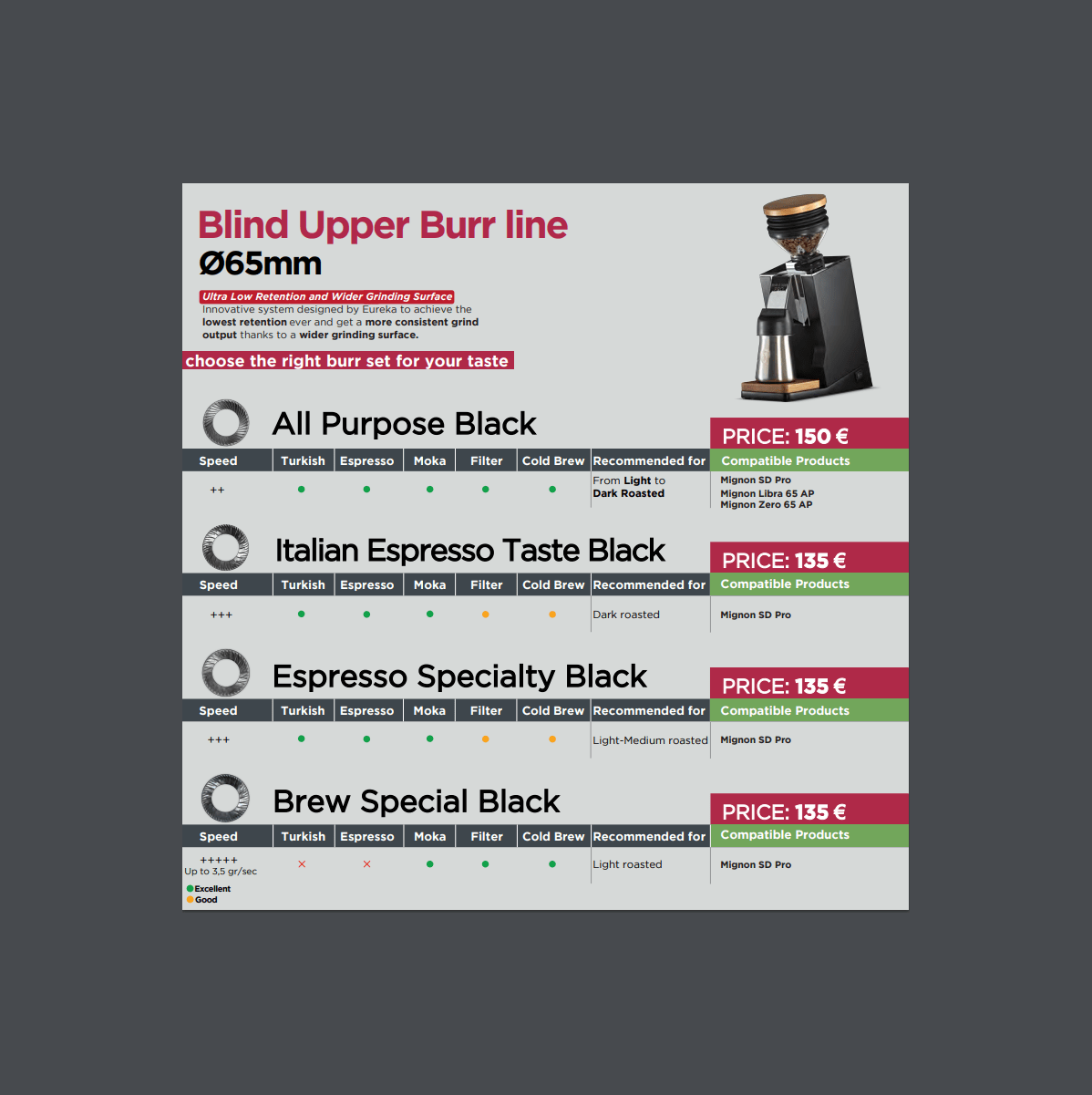

Ultra Low Retention & Wider Grinding Surface

The innovative system developed by Eureka enables the lowest retention ever. The wider grinding surface ensures a more consistent grinding result.

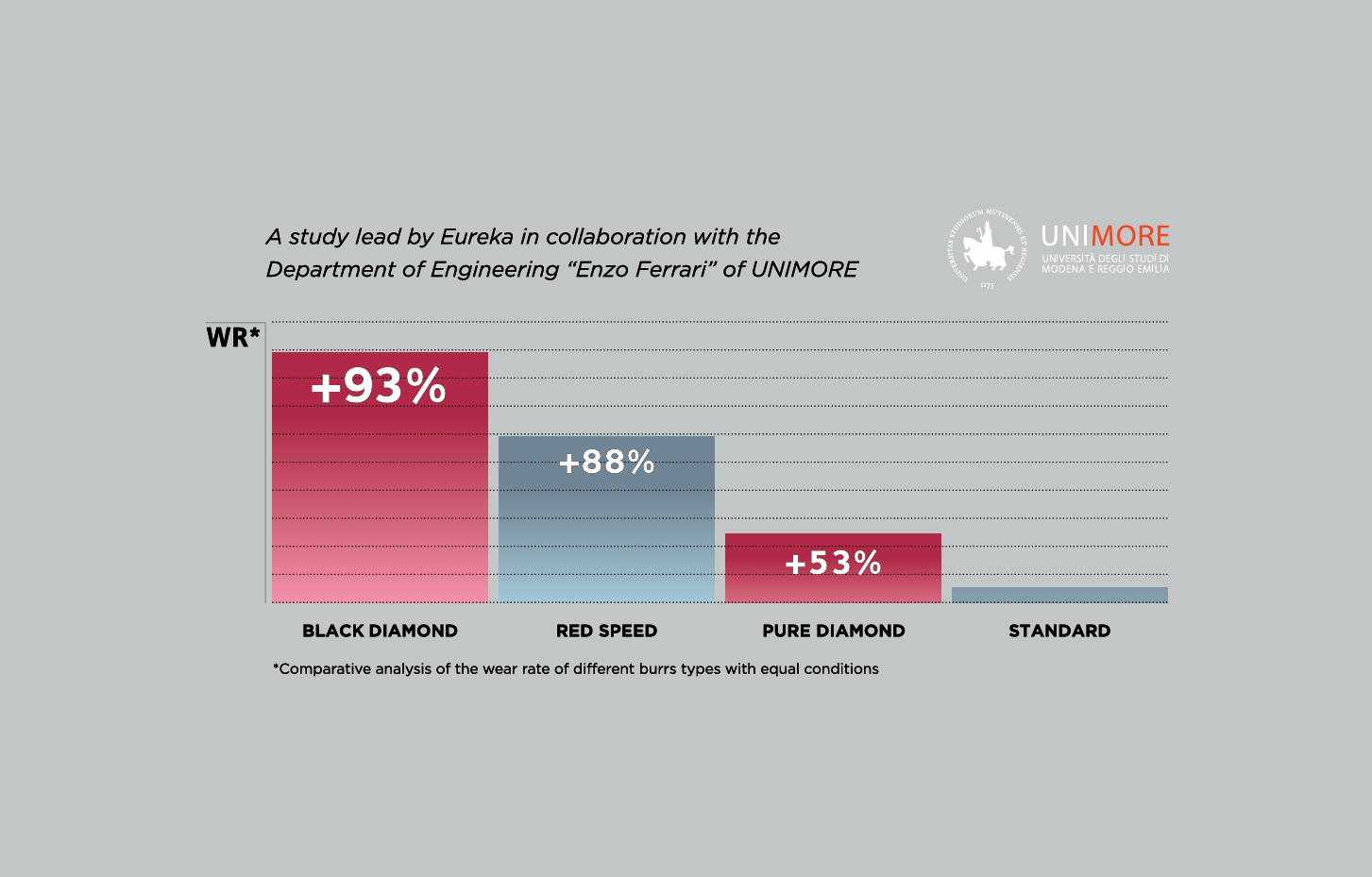

Black Diamond technology

The combination of cryogenic process and DLC coating (Diamond-Like Carbon) guarantees unique performance and durability. Studies by the University of Modena and Reggio Emilia (UNIMORE) show a durability improvement of +5% compared to Red Speed and +93% compared to stainless steel grinding discs.

No coffee loss

The grinding discs are ready for use immediately. Thanks to a special process developed by Eureka, the grinding discs do not need to be "run in", which prevents coffee loss.

Superior grinding consistency

The cryogenic treatment of the grinding discs at -193°C ensures greater wear resistance and maintains the grinding settings longer than any other grinding disc technology.

Diamond Inside grinding discs

Eureka's new patented process ensures a superior crystal structure of the grinding discs. Diamond Inside is a low-temperature thermal treatment process at -193°C that creates an increased crystal structure and thus guarantees superior wear resistance and durability.

This process helps to maintain the optimal geometry of the burrs longer than any other type of burr. The granulometry remains constant for an exceptionally high quantity of ground coffee: about 1300 kg with 65 mm burrs, with a total duration that can reach up to 1500/1600 kg.

Información sobre el fabricante

* Bonität vorausgesetzt. Ratenbeispiel für PayPal Ratenzahlung: effektiver Jahreszins 12,49 % p.a., fester Sollzinssatz 11,80 % p.a., Laufzeit 24 Monate. Genaue Konditionen und Gesamtkosten werden im nächsten Schritt von PayPal angezeigt. Angebot gültig nur für Kunden mit Wohnsitz in Deutschland. Weitere Infos zur Bonitätsprüfung.

If you have any questions, please feel free to contact us at any time. We will get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping info

We ship all products the same day if ordered before 1pm.

-

Soporte

We will also be there to support you and advise you after your purchase. If you have any questions about the product you purchased from us, please contact us.

-

Contact

Email: hello@naturbohne.de

Teléfono: 07454 / 870 48 64

Frequently Asked Questions

I bought a new coffee grinder from Naturbohne and there are coffee residues in it.

Please note: Some manufacturers test their coffee grinders before shipping, which means that small coffee residues or bean residues can occasionally be found in the grinder. This procedure is used to test functionality and is considered a quality feature. Of course, we only sell new products - unless expressly stated otherwise.

Static charge – coffee grounds spray out from the side

With some coffee grinders, the ground coffee can become statically charged and spray out of the portafilter at the side. This means that not all of the ground coffee gets into the portafilter, which can lead to uneven extraction. Our recommendation: Use a dosing funnel to ensure that all of the ground coffee is precisely fed into the portafilter - for optimal espresso enjoyment.

What is dead space in coffee grinders?

Conventional coffee grinders often leave a so-called dead space in which coffee residues accumulate. These residues can not only affect the freshness, but also lead to old and fresh coffee grounds being mixed, which negatively affects the taste. In contrast, single dose grinders have a well-thought-out design that eliminates the dead space. Each portion is ground individually and precisely so that no residues are left behind - for a consistently pure and full-bodied coffee experience.

Which portafilter fits my espresso machine?

When choosing the right portafilter for your portafilter machine, it is important to know that each manufacturer develops its own brewing group - the most well-known is the Faema E61. However, this does not mean that any portafilter will fit without any problems. An incompatible portafilter can leak, which will have a direct negative impact on the quality of your espresso. We therefore recommend using either the portafilter originally supplied or one that is explicitly stated to be compatible with your machine. This will ensure that the pressure is optimally built up and the espresso is perfectly extracted.

Can I visit you or pick up the goods personally?

Yes, of course, you are welcome to come by and look at our products by appointment. We would be happy to advise you personally. The best thing to do is to send us an email with a few suggested appointment times.

We are located 5 minutes from the motorway between Stuttgart and Lake Constance on the edge of the Black Forest.

Important note, first use coffee grinders

Another little tip for the perfect start with your new mill:

You will get the best grinding result after you have ground about 1-2 kg of beans. It is best to use a few cheap beans so that the grinder can work optimally. And if you are wondering what you can do with the bean flour - it is perfect plant fertilizer! 🌿

It contains nitrogen, potassium, sulfur and phosphorus and is a real nutrient bomb for your plants.

¿Pueden realizar una calibración de offset en mi máquina de portafiltro?

Existen varios argumentos en contra de una calibración de compensación en las máquinas de portafiltro Lelit, especialmente en modelos como la Lelit Bianca. Estos se refieren principalmente a la complejidad y las limitaciones de la compensación como única solución para problemas de temperatura:

- Fluctuaciones de temperatura e inestabilidad. La compensación considera una diferencia constante entre la temperatura de la caldera y la temperatura de preparación. Sin embargo, en la práctica pueden ocurrir fluctuaciones de temperatura, por ejemplo, debido a tiempos de espera prolongados o preparación continua. Esto hace que la temperatura de preparación real no siempre sea predecible con precisión.

- Dependencia de las condiciones ambientales. Factores como la temperatura ambiente, la humedad y el estado de la máquina (por ejemplo, el tiempo de calentamiento) afectan significativamente la temperatura de preparación. Una compensación fija no puede equilibrar dinámicamente estas variables, lo que puede llevar a resultados inexactos.

- Pérdida de calor durante los tiempos de espera. Después de pausas prolongadas, el grupo de preparación se enfría y la máquina necesita tiempo para volver a la temperatura deseada. Una compensación correctamente ajustada no puede compensar esto, por lo que son necesarias medidas adicionales como un "Cooling Flush".

- Desajustes de fábrica. En algunos modelos de Lelit se ha encontrado que la compensación de fábrica a menudo está configurada de manera inexacta (por ejemplo, de 4 a 8 grados demasiado baja en la Lelit Bianca). Esto requiere una recalibración manual por parte de personal especializado, lo cual puede ser complicado para los usuarios finales.

- Malentendidos en la aplicación. Muchos usuarios están confundidos por la información contradictoria sobre la configuración de la compensación, lo que puede llevar a ajustes incorrectos. Por ejemplo, a menudo se espera que la compensación por sí sola resuelva todos los problemas de temperatura, aunque solo es parte de un sistema más complejo.

Conclusión

La calibración de compensación es una herramienta útil, pero no debe considerarse de forma aislada. Una combinación de control PID preciso, mantenimiento regular y técnicas adaptadas (por ejemplo, "spülshots") es necesaria para lograr resultados óptimos de preparación.

Do you have any more questions?

Contact

If you have any questions about our products, please write to us here or use the chat function.